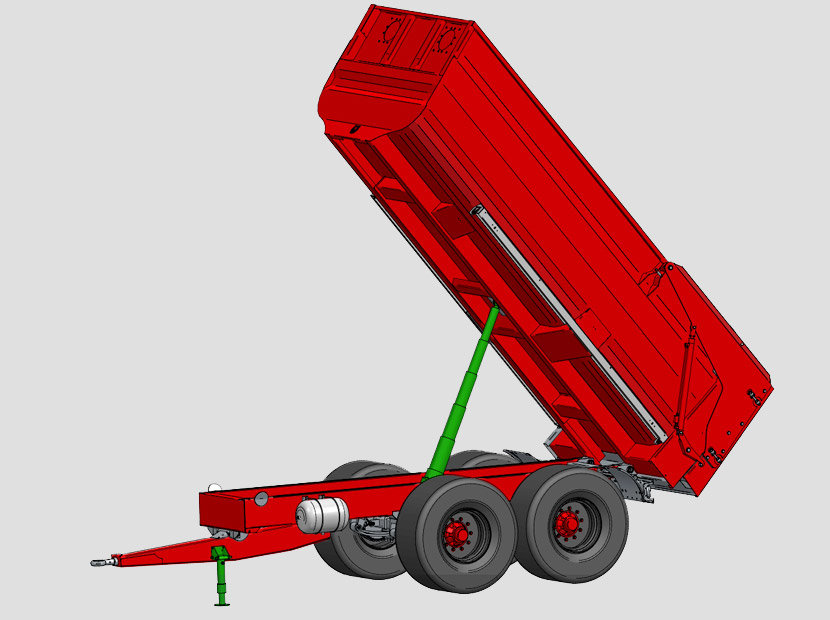

Di Natale - Bertelli spa has a well-equipped and efficient technical office, where a design team studies and implements the proposed solutions.

Thanks to sophisticated software (CAD on 2 workstations), the realization of the finished product is scrupulously analysed, reflecting and managing all the possible variables, which take place during use.

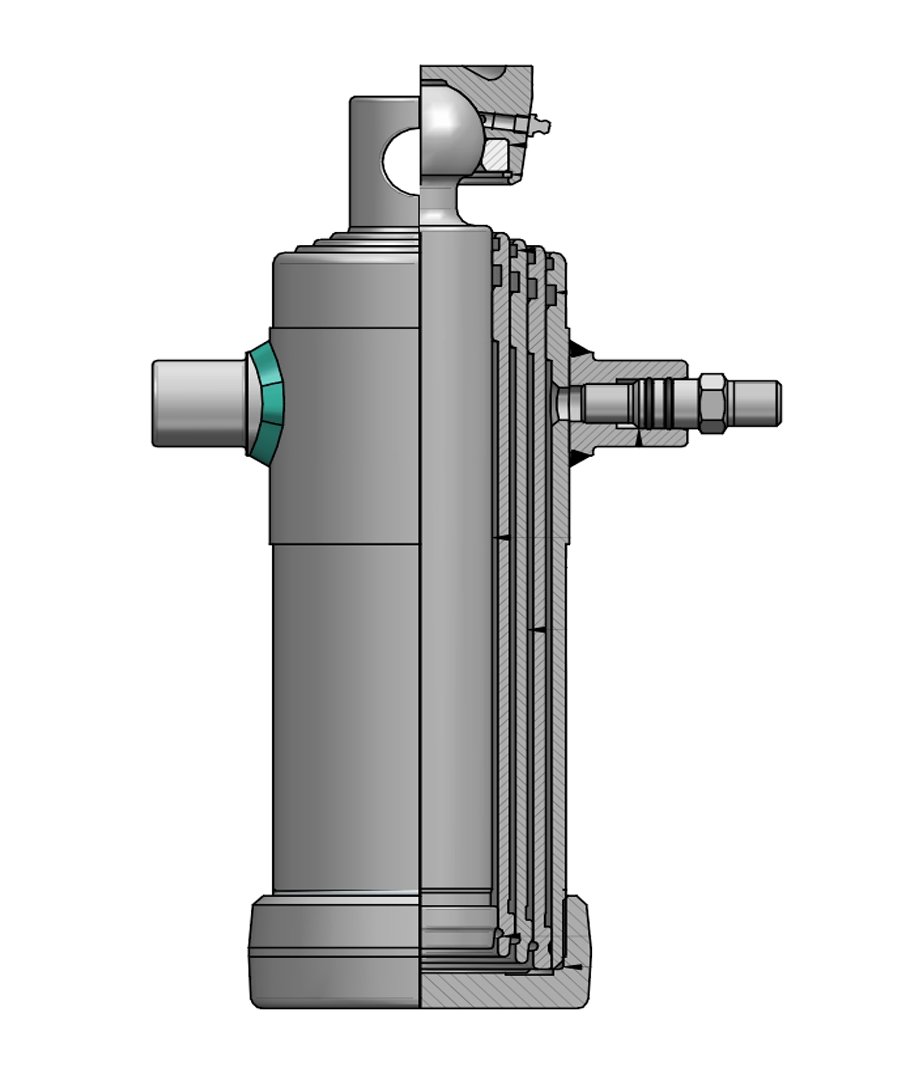

For the components, we calculate precisely the effort and wear to which they will be subjected during use. These calculations are then applied to the entire structure of the telescopic cylinder in order to have a clear understanding of the points of greatest load and effort.

All this is a philosophy, which Di Natale – Bertelli spa applies indiscriminately to everything he does.